Nominees 2022

133 entries from Germany and abroad, including 41 finalists and 15 nominees, were in the running for the top places at the bauma Innovation Award. The new categories of climate protection and digitalisation generated excitement for the first time, and the classic categories of machine technology, construction and research also had a few surprises in store. The industry is innovative, spurred on by the determination to implement environmental and climate protection policy requirements. Each category had three innovations in the final round, and in the end, there were five winners.

Click here for the playlist:

bauma Innovation Award 2022 - YouTube

Here we present the nominees:

Nominees 2022 | Category: Climate protection

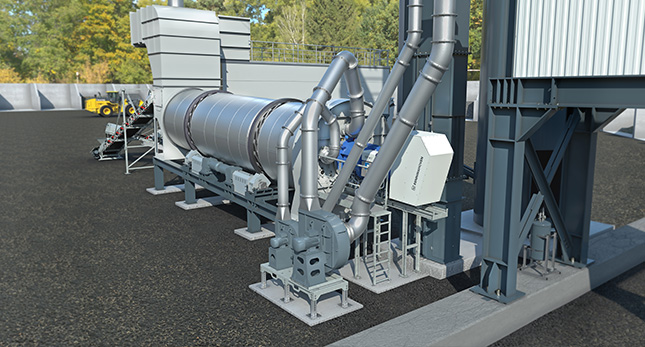

BENNINGHOVEN - Branch of Wirtgen Mineral Technologies GmbH

The Benninghoven REVOC system - catalyser for asphalt mixing plants

Thanks to increased plant performance, high recycling additions and reduced emissions, plant operators are optimally equipped for the future. BENNINGHOVEN presents a new, patented, pioneering technology: the REVOC system. A technology that enables plant operators to realise higher recycling addition rates while complying with strict emission limits.

Further information on the innovation can be found in the press release.

carbonauten GmbH

Minus CO2 building materials - regenerative, better, cheaper

carbonauten - the minus CO2 factory was founded in 2017 with headquarters in Giengen an der Brenz to remove gigatonnes of CO2 from the atmosphere. At global and decentralised locations, biomass residues are turned into CO2-reducing technical biochar. If these are combined with various binders, CO2-reduced, CO2-neutral or even CO2-negative building materials are created.

Further information on the innovation can be found in the press release.

Liebherr France SAS

Crawler excavator with hydrogen engine

In times of climate change, which demands comprehensive measures for environmental protection and in particular the reduction of pollutant emissions, it is one of the tasks of construction machinery manufacturers to develop low-emission solutions. Liebherr is also working on various drive alternatives in different product segments in the interests of its customers in order to make a contribution to reducing emissions.

Further information on the innovation can be found in the press release.

Nominees 2022 | Category: Digitalisation

Bosch Rexroth AG

Haptic collision avoidance

Bosch Rexroth has been nominated for the bauma Innovation Award 2022 with an innovative system for haptic collision avoidance. Based on precise ultrasonic environment detection, the assistance function intuitively warns the operators of excavators, wheel loaders and other construction machinery of impending collisions by vibrating the joystick. The type and intensity of the haptic feedback provides information about the distance to the object.

Further information on the innovation can be found in the press release.

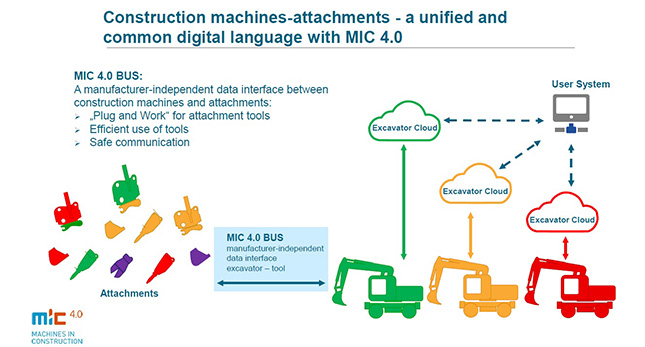

MiC 4.0 Machines in Construction

A standardised digital language for construction sites

Many different construction machines work together on construction sites today. They are becoming more digitalised and virtually networked every day. However, communication between construction machines and their attachments is still manufacturer-specific, but not compatible across manufacturers.

Our innovative solution: the MiC 4.0 BUS, the plug-and-play solution that connects construction machines and their attachments - a standardised cross-machine and manufacturer-independent data interface between construction machines and attachments.

Further information on the innovation can be found in the press release.

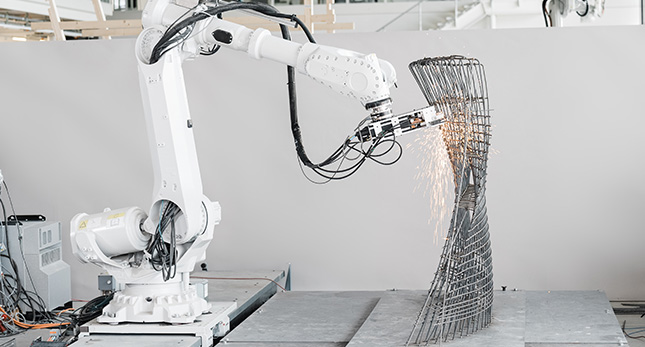

Mesh AG

MESH technology

MESH AG has developed the world's first robot-assisted technology for the production of complex reinforced concrete components without formwork. The innovative production process offers new design possibilities for the construction industry, while at the same time eliminating the need for costly and resource-intensive special formwork. The new robotic construction method therefore makes an important contribution to greater freedom of form, sustainability and efficiency in construction.

Further information on the innovation can be found in the press release.

Nominees 2022 | Category: Mechanical Engineering

Ammann Compaction GmbH

Ammann 3D Compactor eAPX 68/95

The Ammann 3D Compactor eAPX 68/95 is a compactor the likes of which has never been seen before. With it, the user leaves behind the one-dimensional movement of conventional vibratory plates. Four unbalanced shafts arranged in an X-shape allow it to perform curves and changes of direction that are unique for a vibratory plate. Ammann is presenting the prototype of the 3D Compactor eAPX 68/95 as part of the bauma Innovation Award 2022.

Further information on the innovation can be found in the press release.

MBuilt Robotics Inc.

Built Robotics Exosystem™

The Exosystem™ is an easy-to-install retrofit system that transforms any excavator into a fully autonomous excavation robot. It combines sensors, software and safety to deliver the world's first and only fully autonomous upgrade for excavators. With robust hardware and an 8-stage safety system, the Exosystem™ provides contractors with reliable and powerful support for autonomous trenching in different soils, elevations and conditions. It can be installed and calibrated on an excavator in less than a day.

Further information on the innovation can be found in the press release.

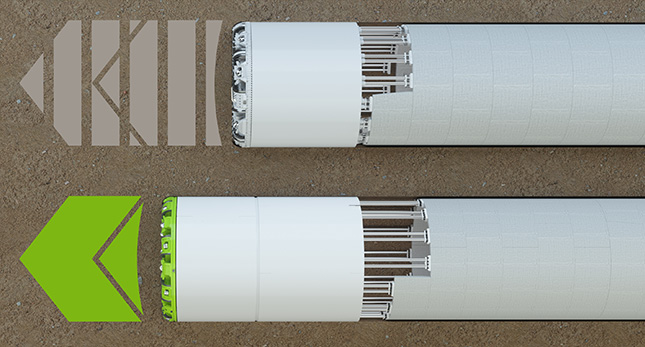

Herrenknecht AG

Continuous propulsion

DHerrenknecht AG is realising the next innovation push for the mechanical construction of high-performance tunnel infrastructures in all common soft ground constellations (soft ground formations with and without water-bearing layers). Continuous tunnelling equipped with the latest high technology leads to a significant reduction in construction times for longer tunnel sections.

Further information on the innovation can be found in the press release.

Nominees 2022 | Category: Building

BAUER Spezialtiefbau GmbH

Process recording system b.navigate

b.navigate - a new process recording system that Bauer Spezialtiefbau has created together with its partners fielddata.io and abaut. This enables the entire construction site process to be mapped and analysed in all its complexity. Using a combination of data from image recognition, intelligent cameras, artificial intelligence and the analysis of drilling rig data, the main and secondary processes are automatically identified and used to optimise the construction site.

Further information on the innovation can be found in the press release.

Max Bögl

TSB - Transport System Bögl - Rethinking local transport

Low-emission, reliable, attractive and rapidly expandable local passenger and freight transport - what was previously only a vision of the future is now becoming reality with the Transport System Bögl (TSB). With the newly developed magnetic railway, the Max Bögl Group is providing an important building block for the mobility turnaround. The TSB is low-emission, causes virtually no noise and can also be realised in densely populated cities thanks to its flexible and modular design.

Further information on the innovation can be found in the press release.

Holcim (Germany) GmbH

Prestressed CPC concrete elements

CPC stands for Carbon Prestressed Concrete. In terms of content, however, CPC stands for resource-saving and climate-friendly concrete components. Instead of the usual steel, the concrete of CPC panels is reinforced exclusively with prestressed carbon fibres. Depending on the design, the high-performance thin concrete slabs enable material savings of up to 80 per cent and reduce the CO2 footprint of the component by up to 75 per cent.

Further information on the innovation can be found in the press release.

Nominees 2022 | Category: Research

RWTH Aachen University

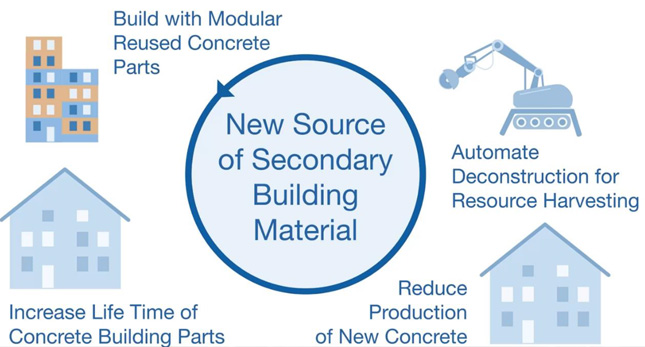

ROBETON, individualised building production

Rising raw material prices and climate change require a rethink of how we deal with existing material resources and existing buildings. By digitally expanding a demolition machine from BROKK into a (partially) automated robot, RWTH Aachen University is developing a new sustainable process for the safe, controlled dismantling and subsequent reuse of concrete components as a source of secondary building products.

Further information on the innovation can be found in the press release.

TU Dresden - Institute of Mechatronic Mechanical Engineering

Site Execution System

Networked and automated construction machinery is the key to more efficient construction processes. The Site Execution System (SES) is the central building block for aggregating all machine and process data on the construction site and orchestrating automated construction machinery fleets. The SES platform integrates planning data and links this with the task description for automated construction machinery. The work results are recorded and assigned to the task descriptions and the underlying planning data.

Further information on the innovation can be found in the press release.

TU Freiberg Institute of Mechanical Engineering

Deep Sea Sampling

Whether copper, cobalt or rare earths, the global demand for these and other raw materials is already enormous. And it will continue to rise in the coming years. In order to meet the demand for raw materials in the long term, existing capacities must be expanded and new deposits sustainably developed. The topic of deep sea mining is therefore more topical than ever. It requires a consideration of the potential and effects across all specialised disciplines. The Deep Sea Sampling research project is making an important contribution to this.

Further information on the innovation can be found in the press release.