Nominees 2025

Who will be the winner? 15 nominees, selected from 52 finalists and a total of 208 entries, are in the running for the top spots in the bauma Innovation Award 2025. Once again, the innovations submitted in all categories did not make it easy for the jury. But in the end, the top three in each category emerged from all the evaluations. The competition shows once again how creative and innovative industry and research are in finding solutions for the economic and environmentally friendly construction of the future. On 6 April, the eve of the opening of bauma, the five winners will finally be presented with their awards.

Click here for the playlist:

bauma Innovation Award 2025 - YouTube

Here we present the nominees:

Nominees 2025 | Category: Climate protection

Hyundai Construction Equipment Europe

H2-Excavator with fuel cell drive

The project to develop a fuel cell powertrain specifically for the HW155H, has been a cooperation between Hyundai Construction Equipment and Hyundai Motor Company. Two fuel cells have been designed, creating 30kW and 50kW of power. The HW155H uses a combination, to provide 70-100kW of power, though the driveline would suit a range of machines, from excavators to fork lift trucks and emergency generators.

Further information on the innovation can be found in the press release.

Robert Thomas GmbH & Co KG

ROTHO ProCarbonCure

With the ProCarbonCure process, large quantities of CO2 can be stored in products made from concrete or steel slag. The process has now been successfully implemented on an industrial scale and has recently been nominated for the BAUMA Innovation Award 2025. The ROTHO ProCarbonCure technology gives concrete products a significantly lower carbon footprint by storing CO2 sustainably and permanently.

Further information on the innovation can be found in the press release.

Wirtgen Group

Local zero emissions construction site

The Wirtgen Group’s modular concept is based on a platform of alternative drive-system solutions. What’s really new is an end-to-end production system that provides everything road construction contractors need for the realization of construction or rehabilitation projects. This includes a cold milling machine, a road paver, a tandem roller, an asphalt mixing plant, a crushing plant, and a whole suite of specially tailored digital solutions. The outcome of all this, a reduction of CO2 and noise emissions and lower operating and energy costs. This in turn enables a more sustainable and simultaneously more profitable project realization.

Further information on the innovation can be found in the press release.

Nominees 2025 | Category: Digitalisation

Liebherr-Werk Bischofshofen GmbH

Liebherr Autonomous Operations

The autonomous driving system developed in-house redefines efficiency and safety in wheel loader operation. The autonomous solution, which is at an advanced stage of development, enables complete driverless operation and is particularly suitable for monotonous standard tasks and operations in hazard zones. “Liebherr Autonomous Operations” features simple, intuitive operation via a web application and allows operators to achieve consistent machine performance over the entire operating period.

Further information on the innovation can be found in the press release.

Wirtgen Group

Smart Automation in Roadbuilding

Smart Automation in Roadbuilding, the new digitalization and automation solution from the Wirtgen Group, exploits system-inherent synergies of the Wirtgen Group machines to make complex technologies more transparent and easier to use. The new solutions enable the realization of precise and cost-efficient paving results in compliance with planned targets with the core construction crew and without additional, specialized personnel. Factors such as costing analyses in advance also enable optimization of the material volumes and logistics required for the realization of the project. All in all, road construction contractors enjoy the benefits of increased planning reliability and predictability of the final results.

Further information on the innovation can be found in the press release.

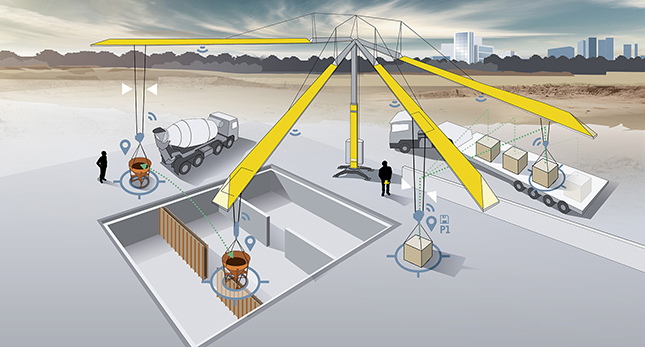

WOLFFKRAN GmbH

WOLFF High-Speed-Positioning-System

The WOLFF High-Speed-Positioning-System (HiSPS) is an advanced technology that revolutionizes crane load control. Through precise, sway-free movement of the load, WOLFF HiSPS provides crane operators with maximum control, safety, and efficiency.

Further information on the innovation can be found in the press release.

Nominees 2025 | Category: Mechanical Engineering

Herrenknecht AG

Tunnel Enlargement System

The Tunnel Enlargement System (TES) developed by Herrenknecht in collaboration with PORR enables the safe renewal and widening of old rail tunnels while rail operations continue. The system simultaneously serves as a carrier for excavation and safety work as well as a protective enclosure for rail traffic. TES has been nominated for the 2025 bauma Innovation Award in the “Mechanical Engineering” category.

Further information on the innovation can be found in the press release.

Liebherr Corporate Ventures AG

S1 Vision – Liebherr Single-Axle Truck

The S1 Vision, Liebherr’s innovative haulage concept with a design that focuses on the core components necessary for moving material, will be on display at this year’s bauma exhibition at the InnovationLab on the Liebherr booth.

Further information on the innovation can be found in the press release.

Liebherr-Werk Biberach GmbH

Positioning Pilot assistance system

The intelligent assistance system Positioning Pilot enables the crane operator to semiautomatically access several stored hook positions without sway and travel individually mapped routes. Safety on site is also increased through the semi-automatic driving of predefined distances. The crane operator is freed from repetitive, monotonous lifting tasks with help from this assistant.

Further information on the innovation can be found in the press release.

Nominees 2025 | Category: Building

Adam Hörnig Baugesellschaft mbH & Co KG

New composite bridge construction method

For the second steel composite superstructure of the Thulba viaduct, Adam Hörnig Baugesellschaft mbH & Co. KG (AHA) opted for a new construction method: the carriageway slab will be constructed using PERI's VCT Cantilever Track system in in-situ concrete. By using the formwork solution travelling underneath the superstructure, AHA is able to construct the carriageway slab without penetrations. In addition, the contractor has the free access from above to reduce cycle times and complete the superstructure more quickly.

Further information on the innovation can be found in the press release.

BAUER Spezialtiefbau GmbH

Dive-Drill Method

Securing the energy supply, protecting the oceans: With the Dive Drill method, Bauer is setting new standards in the construction of offshore foundations. This method combines state-of-the-art technology with expertise obtained over the course of many decades. Whether in stormy seas or hard rock, a drilling rig developed in-house and operated from a vessel makes it possible to build offshore wind parks safely and sustainably even under extreme conditions. Eco-friendliness and efficiency are key aspects here.

Further information on the innovation can be found in the press release.

N1 Circular GmbH

SITE DEPOT material flow management software

Site Depot analyzes service specifications for construction projects and automatically extracts information about which materials are generated or required when, where and in what quality. The innovative software enables construction companies, recycling companies and public waste management authorities to recycle and reuse secondary raw materials in a targeted manner using integrated maps with recycling and disposal options.

Further information on the innovation can be found in the press release.

Nominees 2025 | Category: Research

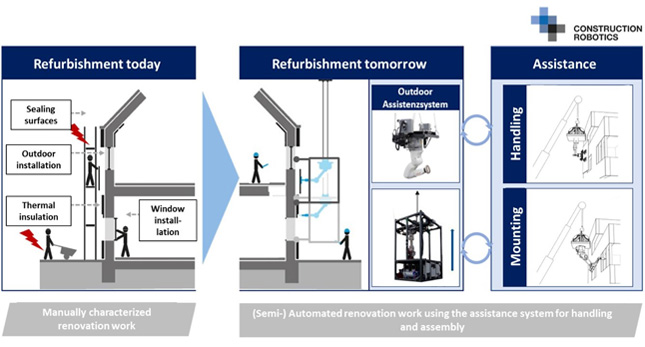

Center Construction Robotics (RWTH)

MAXX - Mobile Assembly X-System

The rate of energy-efficient refurbishment in Europe currently amounts to just 1% of the existing building stock each year. Yet, this sector is responsible for 48% of society's total energy consumption and 35% of CO2 emissions. In the context of the European Green Deal 2050, MAXX – Mobile Assembly X-System provides a first plug & produce solution for (semi-) automated, scaffold-free assembly in building refurbishment. This patented robotic cable platform is adaptive and universally deployable in existing buildings—without extensive data collection or permanent human control.

Further information on the innovation can be found in the press release.

Technische Hochschule Köln

Muck measuring system for EPB tunnel boring machines based on AI (MEGA)

When a tunnel is being constructed, over 200 tons of material can be excavated per hour, which is often disposed of in landfills. The “Muck measuring system for EPB tunnel borinG machines based on AI” (MEGA) innovation allows for an AI-based analysis of the material excavated during operation and thus for a better and more sustainable use of these valuable raw materials. The system was developed within the REMATCH research project conducted by TH Köln and its partners STUVA and Herrenknecht AG.

Further information on the innovation can be found in the press release.

Technische Universität Dresden

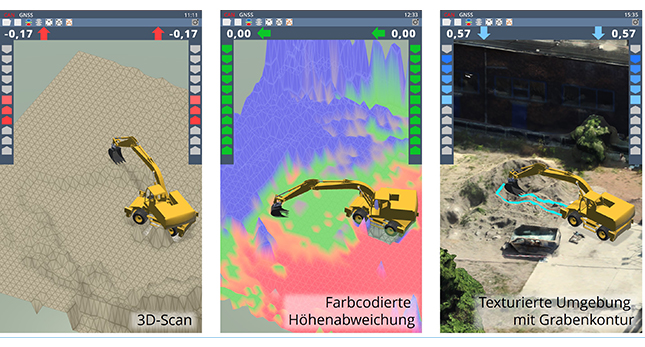

ExtendedExcavatorHMI

The innovation shows new visualization possibilities for excavator operation. Digital information is displayed to the operator in relation to the real environment in an intuitive way. Deviations from the planning model and potential hazards (people, underfloor media) are displayed in the operator's direct field of vision. The use of 3D sensors and AI in conjunction with innovative visualization technologies creates a productive and safe working environment.

Further information on the innovation can be found in the press release.